Our Services

Servicesound Services

Servicesound has been repairing and servicing hi-fi since 1968.

and offer a comprehensive range of service, design and build services.

We also offer a phone help service if the on-line tips and advice doesn't cover your needs but please do look at that first.

Since 1968 Servicesound have had the pleasure of working on some of the finest tape recorders ever made. Personal favourites are Ferrograph and Brenell but all reel to reel tape recorders have a 'mystique' about them. A combination of precision engineering and brilliant electronics leads to sound that cannot be bettered. Many recording studios are now going over to analogue recorders preferring them to the hard clinic al sound digital recorders produced.

Reel to reel machines are beginning to become scarce and expensive, perhaps the most important point is that they can almost always be repaired and bought up like new. This is where Servicesound can help. Almost regardless of make and age, so long as it is intact

Servicesound can repair your tape recorder.

Explanation of reel to reel tape recorder terminology

For those new to reel to reel machines and who wish to obtain a machine to use, you need to be aware of a couple of pitfalls especially if you have tapes that have been recorded on another machine which now need to be played back.

The 'channel / track' confusion -

The channel is the number of electronic recording and playback amplifiers a machine has. A single channel machine is Mono. Two channel machines are stereo and multi track studio machines can range too 24 channels.

Most quarter track machines are either Mono (one channel) or Stereo (two channels).

One confusing element is the track configuration or layout which is explained in more detail in the tips and advice page.

The other aspect you should be aware of is the tape speed. This can range from 15/16 ips to 30 ips (ips = inches per second).

Most home and semi professional machines can be switched between 1: 7/8ips and 3: 3/4ips or between 3: 3/4ips and 7 1/2ips and some three speed machines can include 15ips.

Notes on Ferrograph tape recorders

The Ferrograph tape recorder is, in my opinion, one of the finest sounding machines ever made. The series 7 generation has had a rather bad press due to the rubber parts melting and on the Seven, the head pressure pads causing problems. All these troubles are easily rectified and once serviced and properly set up the Ferrograph will out perform just about any machine you care to mention.

They do have their little idiosyncrasies but this is what comes with a hand made machine and when one gets used to using them they are a joy. Built like a tank and easy to service these machines will go on forever. The electronics are simple and all the parts are easily obtainable. The early, round bodied, heads can be taken apart, finished and micro polished to bring them up like new. The same applies to the older 4, 5 and 6 series. These are valve based machines and have the magic that valves add to the sound.

Servicesound has been chosen as the Ferrograph Service Centre

There are a few machine makes we do not handle:

we do not repair: Philips, Stellaphone, NAGRA or Uher.

We do not repair digital equipment, CD or cassette machines.

We do not repair solid state amplifiers except those manufactured by Ferrograph.

What We Do

Your machine is stripped, inspected and internally cleaned. All controls and switches are checked and cleaned.

The tape transport and all the associated controls, linkages, levers, bearings and operating systems are checked, cleaned and lubricated as required. Brakes are cleaned and if necessary re lined and set up. Any clutches are checked and lubricated and the linings replaced if they are badly worn. Often the clutch pressure needs to be re set as on the Akai 4000 range of machines. On many Tandberg models cork clutch pads are used which disintegrate, these are replaced.

Perished and loose belts are replaced, drum counters cleaned and lubricated, the fast wind torque and speeds are checked as is the play speed.

All the heads and tape guides are checked for wear and micro polished before being degaussed, (demagnetised). If the heads are badly worn, they can often be re faced and polished and you will be notified if this is needed. If the heads are worn beyond use you will be informed and recommendations made as to the best way to proceed.

Pinch rollers, idlers and jockey wheels are cleaned and if they are damaged or irregular, they are reground. If the pinch roller has or is disintegrating you will be notifi ed and a new one fitted if they are obtainable. Often where a replacement pinch roller cannot be sourced, the old one can be rebuilt or a roller from another model can often be adapted. The same applies to rubber idlers and jockey wheels. For instance, most of the Brenell idler wheels can be replaced with those made for Ferrograph. By swapping the centre bearing they will fit and work perfectly.

Electronically, the machine is checked out and any plugs and sockets, connector strips and circuit board connectors are cleaned. Any faults are traced and if serious you will be notifi ed otherwise they will often be corrected under the service. Valve driven machines have all the valves and their sockets cleaned and any leaking capacitors, replaced. The various voltages applied to the valves are checked to make sure they are within accepted values, if not, the problem is corrected. Valves are now easier to buy than ever!

The whole machine is checked for correct operation. The head alignment, playback and recording levels are checked and are adjusted if necessary and the bias optimised. Finally, the tape path is given another clean.

The exterior is thoroughly cleaned and polished including the knobs, trim parts and cabinet, the machine is tested once again and then wrapped in a 'cold cast' plastic film.

It sometimes occurs that parts for very old machines cannot be obtained or rebuilt, but adapted parts from other makes and models can often be made to work perfectly well.

Never give up on a tape recorder that you think cannot be repaired, ingenuity, experience and attention to detail has enabled us to get many machines running perfectly.

There is one exception. Most Philips machines use rubber components that often melt and turn into a black goo. Mostly these Philips machines take so much time to clean that they are simply not worth doing, therefore we no longer handle Philips and their associated marques.

NAGRA and Stellavox machines - Because spares for these machines can only be obtained from authorised dealers who do not sell to the trade, these machines should be returned to the manufacturer for repair.

Ferrograph & Servicesound

Servicesound is the authorised Ferrograph service centre and we offer free advice and support for Ferrograph models.

These are perhaps the best made and best sounding reel to reel machines made. Most of the electronic components used are still available "off the shelf" and the known issues with idler and pinch rollers disintegrating have been completely cured. The heads can often be refaced and polished to as good as new. There are some modifications that have been developed by Servicesound that are mostly associated with all Series Seven machines and address mechanical noise and stability issues. The modifications are included in all overhauls.

Servicesound offer a fixed price complete overhaul for all FERROGRAPH Series Seven machines including the Super Seven and Logic. The fixed price option assumes the machine is completely intact with no missing parts.

Vortexion tape recorders.

Vortexion use the same Wright and Wear decks as used on all Ferrograph machines up to the Series Six however they use their own designed amplifiers which can be expensive to overhaul, also some of the early machines use rubber covered cabling which tends to disintegrate.

Brenell & Servicesound

Servicesound has a vast amount of experience with these machines. There is one major issue with STB1, STB2 and Mk5 models. Some of these machines use German made BOGEN heads which have a habit of going open circuit. The heads are clearly marked BOGEN and seemingly have no wires attached as they go in from underneath. This renders the machine unrepairable unless all the heads are replaced. New replacement heads can be manufactured in America but this is expensive. Please make sure your machine plays back and records, at least to some extent, before considering service.

MINI 8 Studio eight track

We have a lot experience with this mode and are, possibly the best sounding 8 track machine made anywhere by anyone. They are a fairly simple machine but must be properly overhauled in order for them to be reliable. The machine must be accompanied by thepower supply unit along with its cables. Additional items that you might have are; counter, remotecontrol, Varispeed control unit. They do have issues with the pinch roller melting and all the Tantalum capacitors should be replaced on all eight boards.

Valve Amplifier Repairs

Servicesound can offer a complete service for your amplifying needs. From servicing to restoration, from repairs to rebuilds and completely new designs.

The Technology

Valve amplification has been around for over 80 years with most valve technology devised in the 1930's and 1940's. Most modern valve amplifiers are based on this technology. Little is new today apart from the higher specification components available and some of the outrageous prices asked for them. In Servicesound's opinion most of these esoteric parts are based on the 'Emperors new clothes' syndrome. They are very expensive and little different than a similar items at a fraction of the cost. ServiceSound use the best sounding, cost effective parts, which goes back to the design ethic of the 30's and 40's, "Forget what it says on the specification sheet! What does it sound like?"

Valve, Thermionic Valve, Vacuum Tube, Thermionic Device, Electron Tube

The History

An evacuated glass tube containing a Anode or Plate, a Grid, (consisting of a thin wire spiral), and a Cathode which is coated in an emissive material which when heated releases a cloud of electrons. The aforementioned grid is placed in the stream of electrons.

If then a positive potential relative to the cathode is applied to the Anode, a stream of electrons will flow allowing current to be passed. By applying a negative voltage to the Grid, with respect to the Cathode, the stream of electrons, and thus the current, can be controlled to a greater or lesser degree dependant upon the value of the negative voltage.

In very simplistic terms this is the description of an amplifying Triode Valve.

Invented by JA Fleming in 1904 and further improved by Lee de Forest a few years later.

The finest and most reliable valves were the ones made in Europe and the USA up to around the 1960’s when solid state devices stole the march. After then much of the valve manufacturing was moved to the eastern block when countries such is Slavonia and Russia bought up all the machinery used by the likes of Mullard, Brimar, GEC and Mazda, unfortunately the manufacturing tolerances, materials and quality are of a lower quality and the machinery poorly maintained so even those valves considered to be of good quality are nowhere near the specifications laid down by Mullard and Brimar. For instance Mullard manufactured their valves to far exceed the original design brief which is one of the reasons why NOS (New Old Stock) valves are so sought after and valuable. It’s also why modern valves are not as reliable as the originals unless they are used in a less demanding way such as reducing the HT voltages and lowering the current flowing.

We often get valve equipment over 50 years old with the original valves which when measured are still perfect.

Valve manufacturing is coming home. The old British valve make Brimar has been revived and are to begin manufacturing valves in the UK again after over 50 years. A group of business people have got together and bought back the original manufacturing machines from the Eastern Block and are in the process of rebuilding them ready to start production. They are also selling carefully selected and tested valves marked with the original Brimar logo although eventually it is planned to manufacture the valves in-house and to the exacting quality of the originals.

What we do

All valve amplifiers go through much the same procedure. A previously unserviced amplifier will usually need all the power supply high tension capacitors replacing, this along with replacing all the coupling and bypass capacitors will ensure a long and reliable service. Unless the output valves measure perfectly these too are replaced but quite often the smaller driver and input valves are OK especially if they are the original makes used, this also applies to pre amplifiers.

All resistors are checked for value and accuracy and any that have overheated are replaced. The chassis is cleaned inside and out, often there will be dry and or overheated soldered joints, these are remade and if any wires have become burnt with heat these are replaced with PTFE cable.

All the valves and their bases are cleaned and any bases or internal contacts are replaced.

Controls, switches, connectors etc are all cleaned and those that refuse to operate perfectly are replaced. Once everything that needs to be replaced has been, the amplifier is slowly powered up and all the new capacitors aged over a period of an hour to ensure reliability. All the various voltages are checked and anything amiss is corrected.

Those amplifiers with grid bias are set up correctly and then left to settle in for a while.

The maximum output power is measured and then the distortion level. All amplifiers benefit from a reduction in distortion and we try to reduce it to the lowest level possible by altering one or two component values, the amplifi er is then 'soak tested' (which means leaving it on for a long time! not sticking it in the bath and turning the taps on!) and then checked again.

Many amplifiers benefit from updating by either the use of modern components or altering the circuit. Little things like replacing poor speaker terminals with decent ones do make a difference.

Leak Amplifiers

Servicesound has developed an upgrade for the LEAK ST20 and TL12 range of amplifiers. This consists of redesigning the input, driver circuit and power supply feeds resulting in an extended bass response and a faster top end. This does not in any way affect the superb sweetness of this wonderful amplifier. In addition, the silly speaker screws are replaced with proper terminal posts and a fused IEC mains socket fitted along with an on/off switch. The original mains fuse is then used as a 500mA HT fuse for added protection should one of the EL84 output valves fail. The speaker impedance selector panels on the top of the transformers are replaced with a perforated stainless steel grill, this is also done on the mains trasformer. The speaker tappings are now situated underneath and all the transformer wiring replaced with PTFE sheathed cable. All the valves are replaced with either Brimar or Electro Harmonix and the GZ34 rectifier valve is replaced with a plug in solid state alternative, this is an important alteration as the mains transformer is conservatively rated and gets very hot. Replacing the rectifier with a solid state version reduces the loading on the mains transformer by about 20% by virtue of the heater supply no longer being needed, this and the replacement grills ensures the mains transformer runs cooler.

Preamplifiers

Most valve preamplifiers made before 1980 are pretty poor. They have tone controls and complicated switching arrangements, they also have complex feedback systems and poor sockets. All this contrives to ruin the signal, using these preamplifiers with a freshly overhauled and perhaps modified power amplifier will negate most of the advantages gained by all the work done. Often the case and chassis of the original preamplifier can be used as a basis to build a new one thus keeping the looks and gaining the sound quality, Servicesound has often done this with great success.

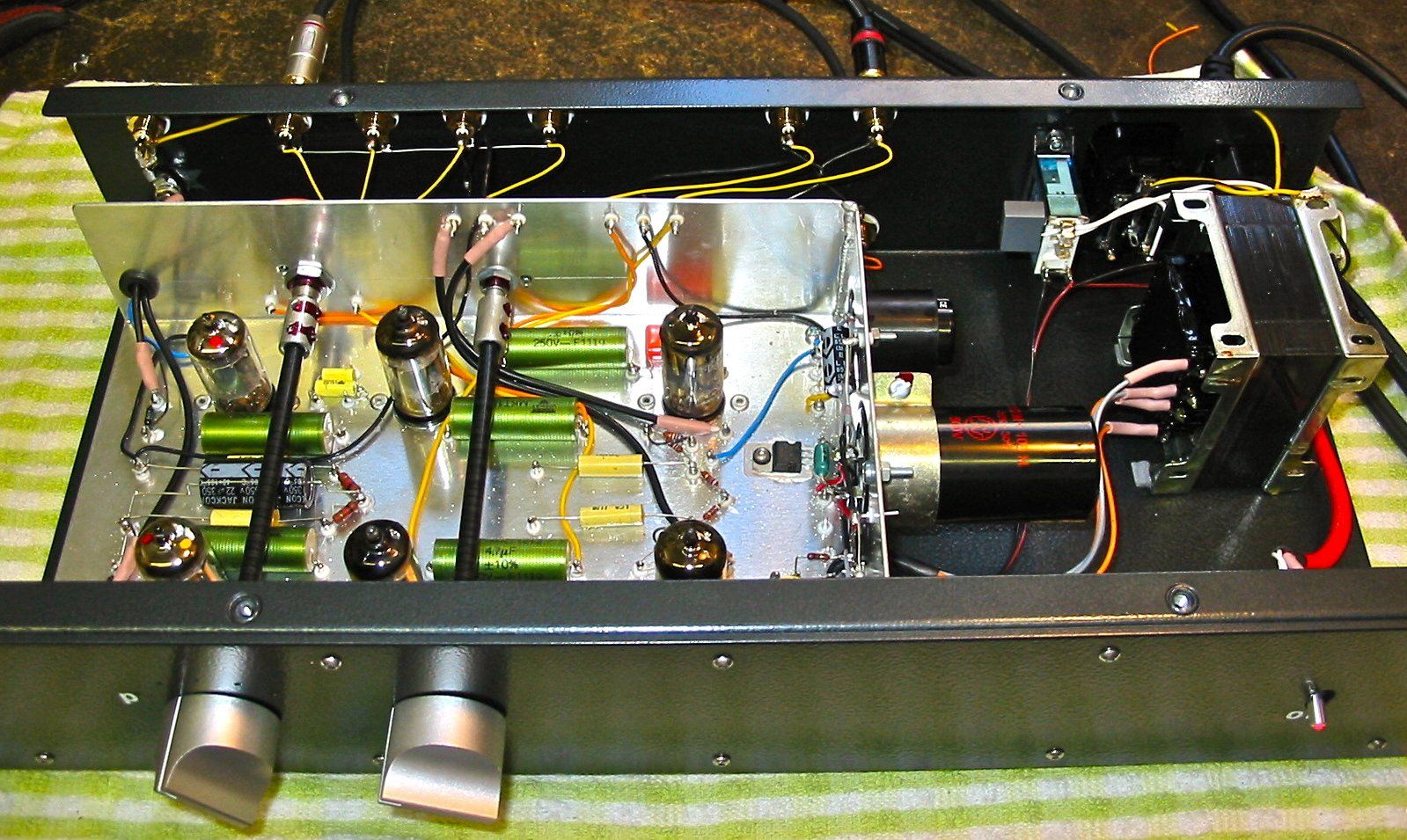

Below is an example of a rebuilt Leak Stereo 20 suite.

Only the the case and knobs have been retained from the original pre-amplifier. The black box on the left is the separate power supply for the pre-amplifier.

The performance far exceeds that of the original pre amplifier plus the line inputs are designed to accept todays high output digital devices.

The phono stage has a modified RIAA equalisation curve that is better suited to todays freshly pressed vinyl which has a wider dynamic range.

The Sound

In Servicesound's humble opinion valve amplifiers sound much better than transistor ones, there are a few exceptions as the Sugden A21 gets pretty close.

People listening to a good valve amp for the first time are 'blown away' by the experience. Valves have a humanity and clarity about them as if they have a 'soul'. Apart from the warmth of the sound there is also the visual aspect of lots of little glass tubes glowing away, a bit poetic perhaps but then ancient technology often is.

Reliability

Some people are of the opinion that valves are unreliable. Valve amplifiers are in fact more reliable than transistor amplifiers. Most of the large airports around the world still run valve driven radar systems because of this. The USA is the world's biggest importer of valves for their radar sets. The Russian defence utility is almost completely valve based. Their fighter planes and ships are valve based. During a conflict valves are much less likely to be damaged from magnetic pulses and interference spikes. It used to be that valves could be left on all the time, 24 hours a day 365 days a year, however that was in the day when valves were made to a much higher quality than they do today. It better for a valve amplifier to be left on so long as it is in use throughout a day but you should turn it off at night.

If a valve does fail it is much less likely to harm its neighbour. Transistors on the other hand can blow up all sorts of other parts when they fail. Good quality valves should last for 10 years or more in fact I have many amplifiers that are over 50 years old with their original valves which still measure perfectly.

Smoke and mirrors

For those who are heavily into hifi and want to improve their listening experience there are many pit falls and traps that should be avoided.

The cable rip off; how about £1000 and more for a set of 1mtr interconnects. It's a con propagated companies that first off all convince you that your currant interconnect or speaker cables cannot possibly be good enough because of all sorts of reasons from, the wire used isn't made of impossiblium (this is a special wire that only conducts music you cannot hear) to insulators made of a material that stops the music from leaking out.

It's all rubbish of course as I have so often proved. Once at a large show I was persuaded by a large dealer to try some eyewateringly expensive cables. £20,000 for a pair of 3mter huge cables that had to be plugged into the mains with their own little power supply, I suppose because they had pretty little blue LED lights buried beneath the woven sheath so they shone though. The cable were about an inch in diameter. When I tried them they totally destroyed the sound, killing the top end and reducing the bass to a wobbly mess. This was using Proteus and a pair of B&W 804S speakers at the London Ramada show.

First of all speaker cables; this should be simple copper, preferably OFC (oxygen free cable) of a decent cross section and should not cost more than a few pounds per meter or even better and cheaper is to get some 2.5mm twin and earth house wiring cable, strip out the blue and brown conductors and use that, tape them together. Do not use any silver with valve amplifiers, it will make the sound brittle and fatiguing to listen to, much like digital.

All in all, most of these boutique manufactures peddle things that not only sound too good to be true, they don't sound very good either. People buy these cables and bits at ridiculous prices and because they are so expensive they spend the rest of their lives trying to convince themselves that yes it sounds better, or does it, it must do, those cables were so very expensive.

Then along I come, put in a bit of household wiring cable and shatter the illusion.

I make no apologies.

The Emperor's New Cloths or

How to spend a fortune making something worse!

I had a customer bring in a nice little American made Cary valve amplifier, I quite like Cary, they have a sound close to the English sound which is an inviting sound except this one wasn't. When the owner bought the amp in New York it was suggested that for another $2000 he could have it upgraded with new special components which will make is sound out of this World. Well, it did sound out of this World, actually it sounded like an alien space craft had landed. It was unstable, distorted and refused to deliver the 20 Watts promised by the manufacturer. Taking the lid off revealed a mess of very expensive paper in oil capacitors, loads of silver cable and variously added and removed bits and bobs throughout the amp, fortunately they had left the original cable-form in place. Once all the added bits had been replaced with ordinary off the shelf decent components and all the silver taken out the amp was reverted to factory spec whereupon it worked perfectly and sounded great. There is a burgeoning cottage industry making special components like paper in oil capacitors claiming they will improve the sound, they will not; a 1 microfarad capacitor is a 1 microfarad capacitor whether it's made of paper in oil or gold leaf. The reason why up to the late 70's manufacturers used paper in oil capacitors is that at that time they offered the lowest leakage v.s. cost available but since the advent of polypropylene and similar materials which offer better insulation and stability characteristics it is no longer necessary to use paper in oil caps for hifi.

And here's another thing, some of the best sounding amplifier made were those made between 1930 and 1960 and they simply used components that were available at the time although it has to be said they were better made, the valves in particular were much better made and to a much higher specification than those made today, indeed, it is little known that the British made valves greatly exceeded the original specifications of the design in both performance and materials.

Today most valves are made in Russia or China and most don't come close to the minimum specifications laid down by the design originators a good example being the Russian made 6C33 double Triode used in the Graaf mono blocks as displayed in the gallery. The reason why a special stability circuit was necessary is that the 6C33 is simply not well enough made to be stable. If the 6C33 were manufactured to decent standards and using better materials the extra circuits would not be needed, unfortunately this applies to many valves made today which is why NOS or New Old Stock valves fetch such high prices.

Custom Built

Valve Equipment

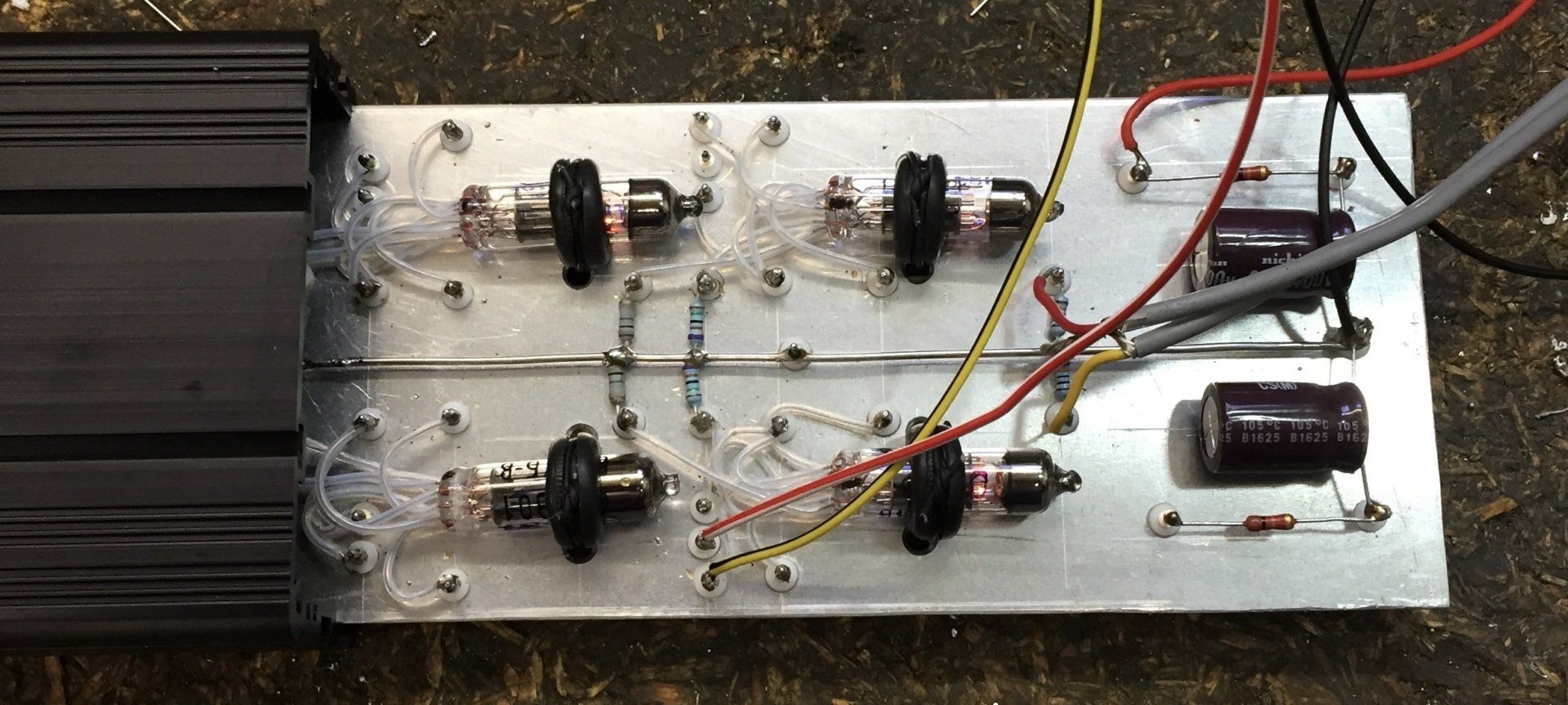

At Servicesound I can help you by building custom valve based equipment to suit your needs.

English Valves Amplifiers Ltd.

Shown above is the Proteus all valve integrated amplifier. Using KT88 output valves in pure Class A push pull is delivers 30 Watts per channel.

The casework is locally hand made out of solid stainless steel. This amplifier was manufactured between 2016 and 2018. Unfortunately the cost of making the casework proved prohibitively expensive. The current EVA amplifier produced is Minuet.

This is the in-house, high quality, hi-fi amplifier manufacturing division of Servicesound. Please visit the dedicated website for more information about the amps I build. www.eva-ltd.com

Modified amplifiers

A majority of amplifiers can greatly benefit from modifications to all areas of their design to improve the frequency response, power output and speed. Where possible Brimar valves are used as part of the modifications. The frequency response is greatly extended with particular attention being paid to the low frequencies where the original design sometimes suffers. The result is that the amplifier will now sound much more precise and open dealing with rock and jazz with ease while still keeping the smoothness and accuracy needed for classical music.

A lot of modern amplifiers are made lacking protection often only having a mains fuse which does not protect against an output valve breaking down. An addition during modifications will be a HT fuse for each output stage.